The Ultimate Guide To "The Key to Boosting Productivity: Production Improvement"

10 Effective Strategies for Production Improvement

In today's competitive service yard, it is essential for business to frequently aim for manufacturing improvement. Through improving productivity and productivity, companies can easily boost their result, decrease price, and acquire a affordable edge in the market. In this blog blog post, we will certainly talk about 10 helpful approaches that can easily aid organizations enhance their production procedures.

1. Simplify Workflow: One of the most crucial actions in strengthening manufacturing is improving the workflow. Analyze the existing procedures and determine any type of obstructions or ineffectiveness. Look for methods to deal with unnecessary steps or automate recurring jobs to make sure a hassle-free circulation of job.

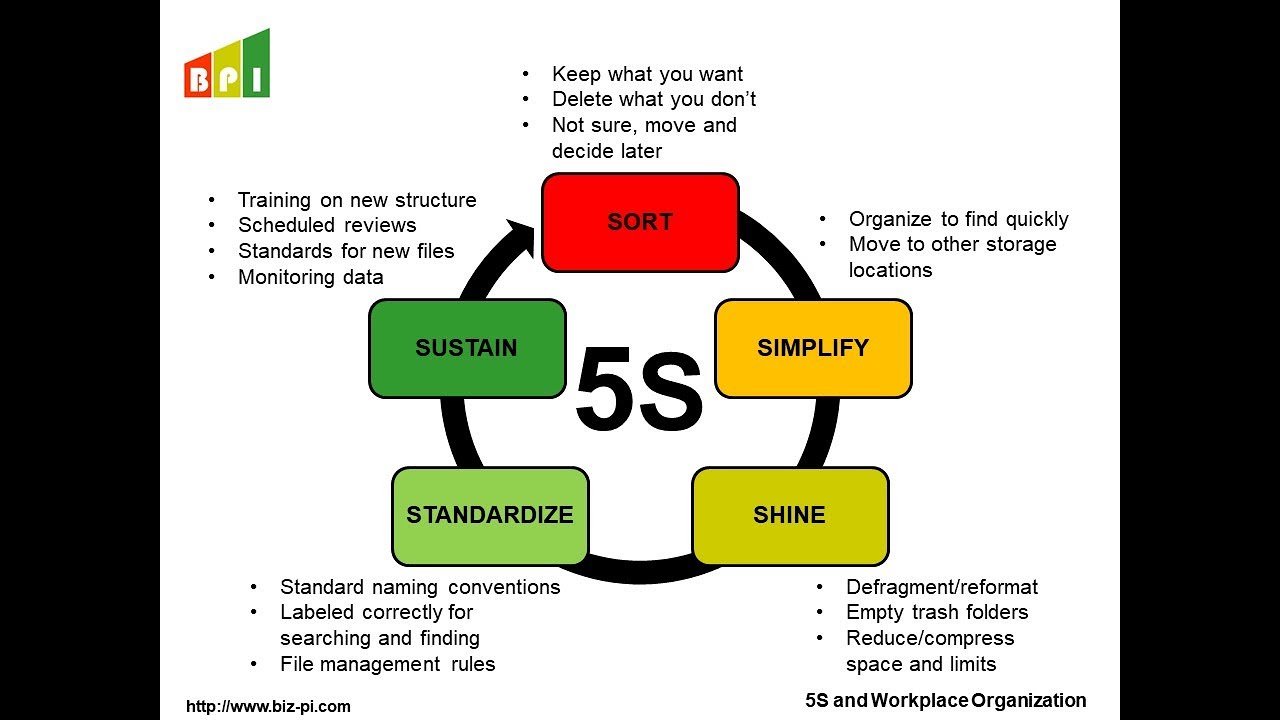

2. Implement Lean Manufacturing Principles: The concepts of lean manufacturing focus on eliminating rubbish and optimizing value-added tasks. Through using slim guidelines such as just-in-time stock management and ongoing improvement, services can significantly enhance their production procedures.

3. Spend in Technology: Taking advantage of modern technology can possess a transformative impact on creation renovation. Executing sophisticated software devices, hands free operation devices, and robotics may enrich efficiency through lessening hands-on inaccuracies, boosting rate, and enhancing accuracy.

4. Give Employee Training: Well-trained workers are necessary for reliable manufacturing methods. Put in in training plans to furnish your workforce with the needed skill-sets and knowledge required to do their tasks successfully. Regularly evaluate training demands and provide ongoing learning opportunities.

5. Specified Realistic Goals: Accurately define manufacturing goals that are realistic however challenging sufficient to stimulate employees. Break down these objectives into smaller sized manageable aim ats that can easily be tracked consistently to make sure improvement is being helped make.

6. Improve Supply Chain Management: A well-managed supply chain is necessary for soft operations and prompt shipment of goods or services. Work together carefully with vendors to optimize supply amounts, decrease lead opportunities, and do away with any type of inabilities in the supply establishment network.

7. Boost Communication Channels: Effective interaction is vital to productive manufacturing remodeling efforts. Set up crystal clear channels of interaction between different divisions involved in the creation process. Encourage available dialogue, reviews, and suggestions coming from workers to pinpoint places for improvement.

8. Carry out Quality Control Measures: High quality control is important to guarantee that products or solutions satisfy consumer assumptions. Carry out strong premium command solution throughout the manufacturing method to find and rectify any defects or issues before they arrive at the final phase.

9. Continuously Track and Assess Performance: Frequently track crucial efficiency indicators (KPIs) related to manufacturing procedures. Analyze record to determine trends, anomalies, or regions where functionality can be enhanced even more. Use this relevant information to create data-driven decisions and implement enhancements accordingly.

10. Foster a Culture of Continuous Improvement: Lastly, generate an company society that values ongoing improvement. Promote employees at all degrees to contribute tips for enriching development processes and compensate cutting-edge solutions. Through fostering a culture of continual remodeling, organizations may make certain long-term success in an ever-evolving marketplace.

In verdict, strengthening development processes is essential for organizations seeking development and profitability. By carrying out A Reliable Source – enhancing workflow, taking advantage of slim concepts, putting in in modern technology, delivering worker training, specifying practical objectives, optimizing supply establishment administration, improving communication networks, carrying out high quality control action, monitoring performance consistently, and cultivating a society of continuous improvement – companies may accomplish significant remodelings in their manufacturing capabilities and remain ahead of the competition.

Keep in mind that steady examination and refinement are vital for sustained results in today's compelling organization atmosphere.